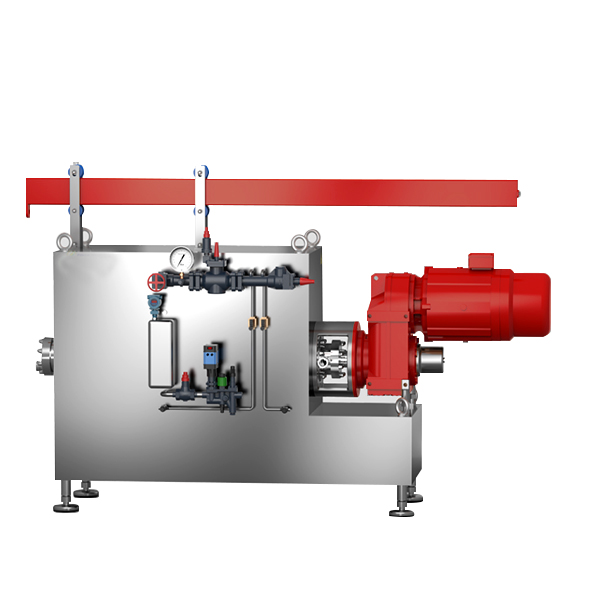

Model Penukar Panas Permukaan Kerok SPSV Pemasok Cina

Produsen lan Supplier Penukar Panas Permukaan Kerok, Votator & Perfector Tiongkok. Perusahaan kita duwe Penukar Panas Permukaan Kerok, Votator & Pefector Tiongkok sing didol, sugeng rawuh kanggo ngubungi kita.

Aplikasi

Penukar panas permukaan kerok seri SPSV (Super Votator) dirancang khusus kanggo industri panganan viskositas dhuwur, iki cocog banget kanggo produsen panganan margarin puff pastry, margarin meja, lan shortening. Iki nduweni kapasitas pendinginan sing apik banget lan kapasitas kristalisasi sing apik banget. Iki nggabungake sistem pendinginan kontrol tingkat cairan Ftherm®, sistem pengaturan tekanan penguapan Hantech, lan sistem pengembalian minyak Danfoss. Iki dilengkapi struktur tahan tekanan 120bar minangka standar, lan daya motor maksimum sing dilengkapi yaiku 55kW, cocok kanggo produksi produk lemak lan minyak terus-terusan kanthi viskositas nganti 1000000 cP.

Mesin Kompetitif sing Padha

Pesaing internasional saka SPSV SSHE yaiku seri Perfector, seri Nexus lan seri Polaron SSHE ing sangisore gerstenberg, seri Ronothor SSHE saka perusahaan RONO lan seri Chemetator SSHE saka perusahaan TMCI Padoven.

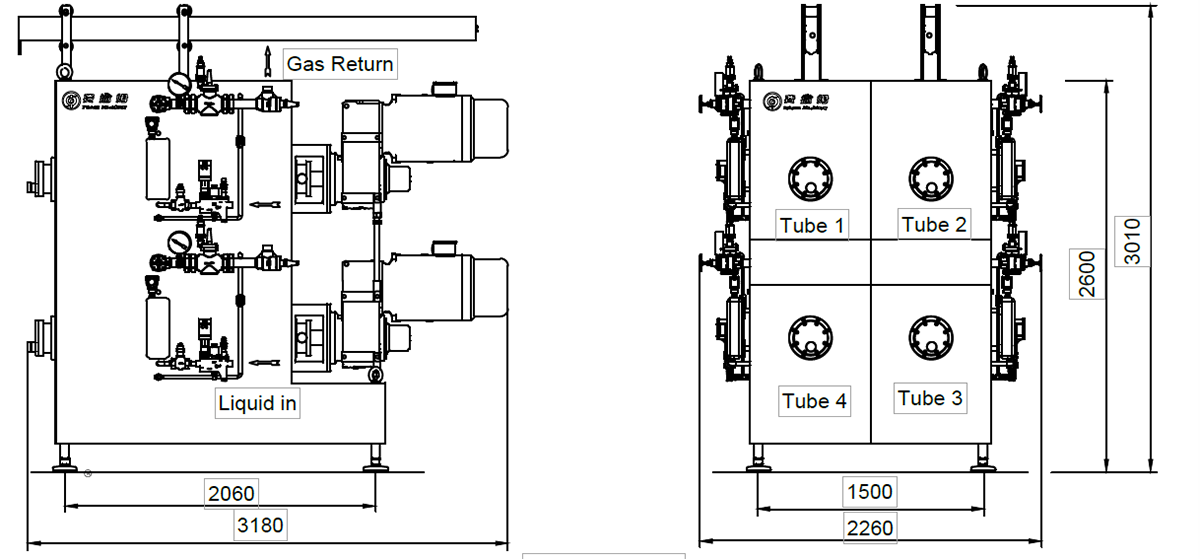

Spesifikasi Teknis

| Seri Super Votator | SPSV-16/1 | SPSV-16/2 | SPSV-16/4 | SPSV-18/1 | SPSV-18/2 | SPSV-18/4 |

| Kapasitas Nominal Margarin Puff Pastry @ -20°C (kg/jam) | Ora Ana | 1150 | 2300 | Ora Ana | 1500 | 3000 |

| Tabel Kapasitas Nominal Margarin @-20°C (kg/jam) | 1100 | 2200 | 4400 | 1500 | 3000 | 6000 |

| Pemendekan Kapasitas Nominal @-20°C (kg/jam) | 1500 | 3000 | 6000 | taun 2000 | 4000 | 8000 |

| Cacahing sirkuit Refrigeran | 1 | 2 | 4 | 1 | 2 | 4 |

| Cacahing Tabung saben sirkuit Refrigeran | 1 | 1 | 1 | 1 | 1 | 1 |

| Motor kanggo Margarin Puff Pastry (kw) | Ora Ana | 22+30 | 18.5+22+22+30 | 37+45 | 30+37+45+55 | |

| Motor kanggo Margarin Meja (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+30+37+45 |

| Motor kanggo Shortening (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+22+30+30 |

| Jumlah Kothak Gir | 1 | 2 | 4 | 1 | 2 | 4 |

| Permukaan Pendingin saben Tabung (m2) | 0.61 | 0.61 | 0.61 | 0.91 | 0.91 | 0.91 |

| Ruang Lingkaran (mm) | 10 | 10 | 10 | 10 | 10 | 10 |

| Kapasitas @ -20°C (kw) | 50 | 100 | 200 | 80 | 160 | 320 |

| Tekanan Kerja Maks. @ Sisi Media (Bar) | 20 | 20 | 20 | 20 | 20 | 20 |

| Tekanan Kerja Maks. @ Sisi Produk (Bar) | 120 | 120 | 120 | 120 | 120 | 120 |

| Suhu Kerja Minimal °C | -29 | -29 | -29 | -29 | -29 | -29 |

| Dimensi Tabung Pendingin (Diameter/Dawa, mm) | 160/1200 | 160/1200 | 160/1200 | 180/1600 | 180/1600 | 180/1600 |

| Volume Produk saben Tabung (L) | 8.6 | 8.6 | 8.6 | 10.5 | 10.5 | 10.5 |

| Pipa Produk Inlet/Outlet (mm) | DN50 | DN50 | DN50 | DN50 | DN50 | DN50 |

| Baris-baris Scraper | 4 | 4 | 4 | 4 | 4 | 4 |

| Kacepetan Rotor Scraper Nominal (rpm) | 340 | 340 | 340 | 240 | 240 | 240 |

| Kapasitas Atemperasi Banyu (kw) | 6 | 6+6 | 6+6+6+6+6 | 6 | 6+6 | 6+6+6+6+6 |

| Volume Atemperasi Banyu (L) | 30 | 30 | 60 | 30 | 30 | 60 |

| Pompa Sirkulasi Banyu (kw) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

Gambar Peralatan

Komisioning Situs